Advantages of metal stamping

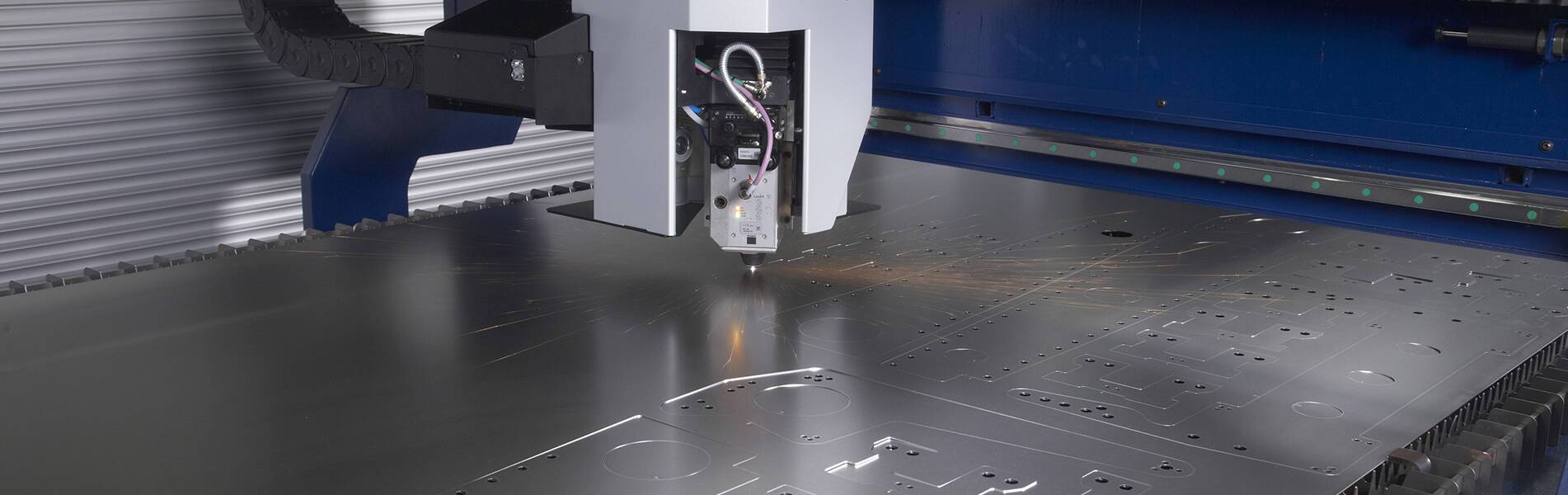

The rapid development of science and technology brings about the improvement of production level. With the rapid development of industry, advanced metal stamping technology has been widely used in our country. Now let's talk about what metal stamping is and its advantages:

1、 What is metal stamping

Metal stamping is a processing method of cutting and forming metal plate or coil by using punch and die, so as to deform or break it, achieve a process with certain shape and size, produce plastic deformation or separation, and obtain the workpiece with the required shape and size.

2、 Advantages of metal stamping plant

1. For smaller products, manual presses are also used to produce workpieces; High quality and low price, quality assurance, exquisite workmanship, professional customization, novel style, with the characteristics of thin, uniform, light and strong. The equipment can not only press metal materials, but also press soft materials such as plastic sheets and packaging paper that need mass production.

2. Stamping can make workpieces with stiffeners, ribs, undulations or flanging that are difficult to be manufactured by other methods, so as to improve their strength and toughness. If precision dies are used, the workpiece accuracy can reach micron level, with high repetition accuracy and consistent specifications, and holes, sockets, bosses, etc. can be stamped. The multi station continuous die can produce hundreds of pieces per minute.

3. In a short time, complete the processes such as feeding, stamping, parts out and waste discharge. Generally, metal stamping is no longer processed by cutting, or only a small amount of cutting is required.

Categories

latest blog

© Copyright: 2025 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Scan to WhatsApp