Manufacturing Metal Stamping

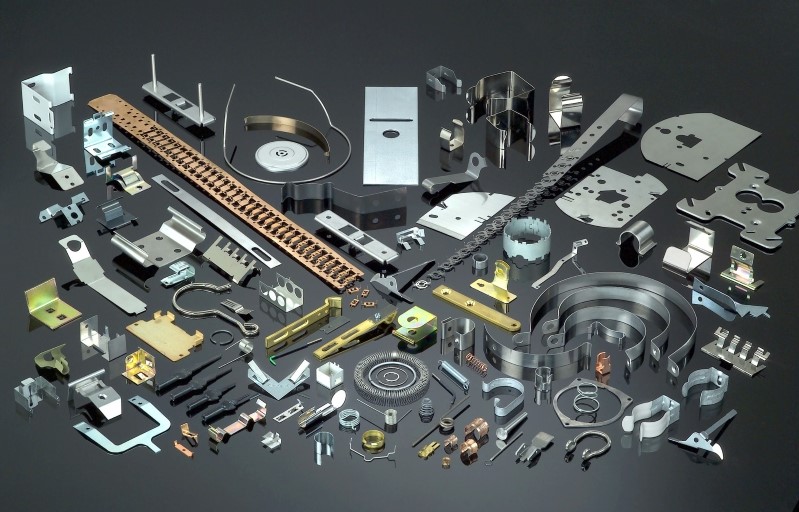

Metal stamping is a cold metal working process that involves the use of dies and stamping presses to shape, form, and manufacture complex parts and components. The various metal-stamping processes include blanking, bending, punching, and piercing, producing distinct shapes and configurations. Metal stamping is a fast and cost-effective method for producing large quantities of parts with excellent tolerances.

In its most basic form, metal stamping is pressing a flat sheet of metal into various shapes using a stamping press and stamping die. The die produces the desired shape of the piece to be pressed.

There are several different types of stamping presses, all of which have the same function. The press has a ram that applies downward force against the sheet of metal that rests on the bed of the press.

Presses take several shapes and forms and depend on some type of power to provide stamping force. Mechanical presses exert force using a flywheel, single-gear design, double-gear design, or some form of eccentric gear design. Hydraulic presses are powered by a hydraulic pump and hydraulic cylinder that drive the ram downward.

Stamping dies shape a metal sheet using a punch that pushes the metal sheet through the die. Punches can be single or multistage depending on the requirements of the final part. With single-stage (or single-stroke) stamping presses, one stroke of the ram produces the desired shape. Multistage stamping presses shape a metal sheet with progressive stamping.

Parts produced using metal stamping are subjected to secondary processes designed to plate, clean, heat treat, or deburr the finished piece. There are several different value-added services based on one’s metal-stamping part requirements.

We invested a bit more budget in mold making, electronic components terminal stamping, and other precision metal stamping parts research and development technology. We strive to provide customers with more reliable technical support and product services.

We’ll be glad to offer you a quick reaction, if you need a reliable manufacturer that gives you your money’s worth, just contact us.

Categories

latest blog

© Copyright: 2026 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Friendly Links :

More ProductsScan to WhatsApp