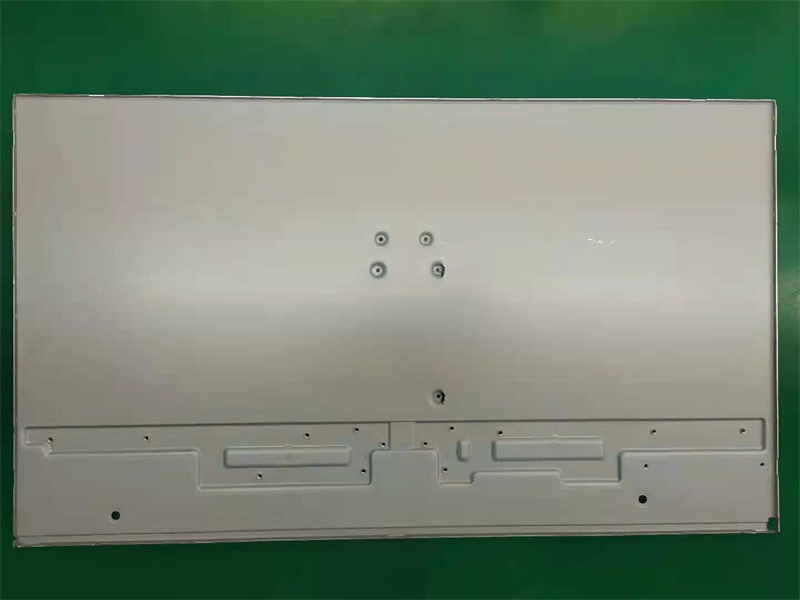

Our Durable Galvanized Steel Hardware Stamping Display Accessories are durable, rust-resistant, and ideal for industrial or retail displays. Made from high-quality galvanized steel, they can be fullycustomizedin size, shape, and finish to suit your project needs. OEM and bulk orders are available.

Item No.:

JX2509004Product origin:

Xiamen,ChinaShipping port:

Xiamen,China

Durable Galvanized Steel Hardware Stamping Display Accessories – Your Technical Manufacturing Partner

Specification

Material Quality

SECC (HV90-100)

Single Weight

1403 g

Surface Treatment

Baking paint, silk screen printing

Working Procedure:

1. Bulging 2. Shaping 3. Trimming & punching 4. Trimming & tooth extraction 5. Deburring 6. Shaping 7. Tooth tapping 8. Paint baking / silk screen printing 9. Packaging

Application

Graphoscope, industrial and retail displays

Our custom galvanized steel hardware stamping display accessories are made from high-quality SECC galvanized steel (HV90-100) using a 200t automatic transmission mechanical stamping system. The production process involves multiple precision operations including bulging, shaping, edge cutting, punching, tooth extraction, deburring, and tooth tapping. After stamping, the accessories undergo cleaning, baking paint, silk screen printing, and other surface treatments to ensure excellent durability, corrosion resistance, and aesthetic finish.

These hardware accessories are fully customizable to meet your specific display requirements, including size, shape, and surface finish. Ideal for applications such as graphoscopes, retail displays, and industrial display setups, they provide strong support, precise fit, and long-lasting performance. OEM and bulk orders are available.

Production Process

Our accessories undergo multiple precision operations to guarantee quality and reliability:

Bulging – Initial forming of the basic shape.

Shaping – Refining contours and edges.

Trimming and Punching – Accurate cutting and hole punching.

Trimming and Tooth Extraction – Ensures precise fit.

Deburring – Removal of sharp edges and imperfections.

Final Shaping – Ensuring uniform dimensions.

Tooth Tapping – Creating threaded or functional sections.

Surface Treatment – Cleaning, baking paint, and silk screen printing for a polished, corrosion-resistant finish.

Packaging – Secure packing for safe delivery.

Features

High Durability : Made from SECC galvanized steel, resistant to rust and corrosion.

Precision Manufacturing : Multi-step stamping ensures consistent quality and precise dimensions.

Customizable: Supports OEM and bulk orders; customizable in size, shape, and surface finish.

Professional Finish: Baking paint and silk screen printing provide a clean, professional look.

Wide Applications: Ideal for graphoscopes, retail displays, industrial setups, and more.

Your Vision, Our Customization Mission

Precision Tailoring Without Limits – Your Partner for Bespoke Automotive Solutions

Feedback Provision

Final Approval

Your Supply Chain, Our Integrated Mission

Materials to Assembly – Your Seamless Manufacturing Partner from Raw Materials to Finished Products

As a direct manufacturer with established partnerships with leading material suppliers, we maintain full control over our production processes. This allows us to offer competitive pricing without compromising on quality, ensuring you receive high-performance components tailored to your exact requirements.

Proven Expertise and Reliable Capacity

Backed by extensive experience in serving diverse industries, we combine technical excellence with scalable production capabilities. Whether you require prototypes or high-volume orders, our team is equipped to deliver precision-engineered solutions with unwavering reliability.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Friendly Links :

More ProductsScan to WhatsApp