What Are Metal Stamping Terminals and Where Are They Used

You use metal stamping terminals to connect wires or cables to devices, allowing electricity to flow safely and efficiently. These terminals come from conductive metals like copper or brass and can be shaped for different uses. Manufacturers rely on them for their durability and precision. You find metal stamping terminals in many industries, including electronics, automotive, and construction, because they offer reliable performance and support complex designs.

| Function | Description |

|---|---|

| Blanking | Forms the base shape with automated punching. |

| Bending | Shapes material for exact fit and position. |

| Deep Drawing | Creates three-dimensional parts for precise needs. |

| Fine Blanking | Improves cut quality for better electrical contact. |

| Local Forming | Adds strength and stability to the terminal. |

| Progressive Stamping | Automates forming, cutting, and inspection for higher output. |

You use metal stamping terminals to create secure electrical connections in many devices. These terminals come from flat sheets of metal, shaped by machines called presses and dies. You find them in products that need reliable power flow, like cars, computers, and home appliances. Metal stamping terminals help you connect wires quickly and safely. Their design lets you fit them into tight spaces, making them ideal for modern electronics.

When you choose metal stamping terminals, you get parts that offer high conductivity and low resistance. These qualities mean your devices work efficiently and lose less energy. You also benefit from their durability. Metal stamping terminals handle heat and tough conditions without breaking down. Their small size saves space, and their strong grip lowers the risk of loose connections.

Tip: If you need to build something that lasts, pick terminals made with high-quality materials. This choice helps your project stay safe and reliable.

You should look at several important features when you select metal stamping terminals. These features help you decide which terminal fits your needs best.

| Characteristic | Description |

|---|---|

| Precision in manufacturing | Ensures accurate dimensions and fit for the terminals. |

| Quality of materials used | High-quality materials enhance durability and performance. |

| Design and functionality of molds | Well-designed molds contribute to efficient stamping and consistent product quality. |

| Stability of the stamping process | A stable process minimizes defects and ensures reliable output over time. |

| Resistance to thermal expansion | Terminals maintain stable contact force in varying temperatures, ensuring reliable operation. |

| Consistent insertion/removal feel | Provides a clear tactile feedback, preventing misjudgment during assembly line operations. |

You also need to think about the advantages of using metal stamping terminals compared to other connectors.

| Feature | Description |

|---|---|

| High Conductivity | Moves power well using copper or aluminum |

| Low Resistance | Less power loss, saves energy |

| Durability | Handles high heat and tough conditions |

| Space Efficiency | Small size saves space |

| Enhanced Safety | Lowers risk of loose connections and faults |

| Improved Efficiency | Low resistance and better conductivity |

| Scalability | Easy to add more circuits or loads |

| Cost-Effectiveness | Saves money on maintenance over time |

You start making metal stamping terminals by following a series of steps. First, you select the right metal and design a custom die for your project. Next, you cut flat metal sheets into specific shapes. You bend or form these blanks to match the shape you need. You add holes or cutouts to the metal, then trim away any extra material. This process is widely used to produce high-precision stamped automotive electrical terminals that require tight tolerances and consistent performance. After shaping, you finish the surface to improve quality. Finally, you inspect each part to make sure it meets your standards.

You need to follow strict quality control when you make metal stamping terminals. You track customer specifications and production dimensions at every step. You use advanced equipmwnt like Zeiss CMM and Keyence vision systems to measure parts accurately. Statistical Process Control (SPC) helps you maintain critical dimensions and spot problems early.

| Quality Control Measure | Description |

|---|---|

| Industry Certifications | Achieve required certifications to ensure quality. |

| Dedicated Quality Lab | Use a lab and inspection team for quality control. |

| Advanced Inspection Equipment | Measure parts with high-end tools for accuracy. |

| Team Responsibility | Make quality a shared responsibility. |

| Supplier Approval Process | Qualify suppliers to ensure material quality. |

You also use documented Quality Assurance actions in every phase. Inspection tools like Nikon Optical Comparators help you track specifications. By following these standards, you make sure your terminals are safe and reliable.

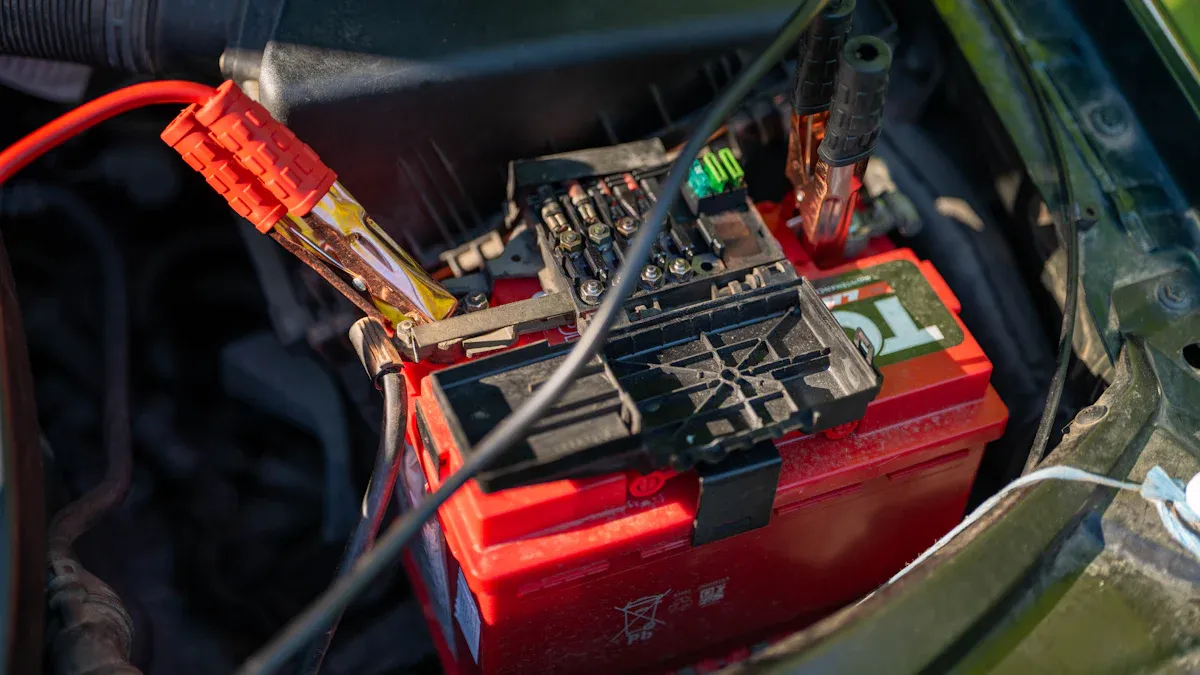

You see metal stamping terminals in almost every part of a car’s electrical system. These terminals help connect wires and parts, making sure your car runs safely and smoothly. Here are some common uses:

These parts must work every time you start your car or use its features. The durability of metal stamping terminals keeps your car’s systems safe, even in tough conditions like heat, cold, or vibration.

Categories

latest blog

© Copyright: 2026 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Friendly Links :

More ProductsScan to WhatsApp