Our High Precision Hot Galvanized Sheet Metal Stamping Motor Cover is crafted from premium DX53D+Z galvanized steel and processed with a 300T high-tonnage punch to ensure excellent precision, strength, and durability. Each piece weighs 196.5g and undergoes a strict procedure of blanking, punching, stretching, cleaning, and packaging. With superior corrosion resistance, stable performance, and reliable quality, it is the perfect choice for electric machinery and motor applications.

Item No.:

JX2509002Product origin:

Xiamen,ChinaShipping port:

Xiamen,China

Professional metal stamping motor cover manufacturer, providing one-stop OEM services from design to mass production

| Product Name | High Precision Hot Galvanized Sheet Metal Stamping Parts Metal Stamping Motor Cover |

| Material | DX53D+Z (deep-drawing grade hot-dip galvanized steel sheet) |

| Piece Weight | 196.5 grams (customizable upon request) |

| Part Type | Extruded hardware parts, motor covers, protective housings |

| Core Technology | Stamping, drawing, blanking, punching |

| Processing Equipment | 300-ton precision punching press |

| Surface Treatment | Hot-dip galvanizing (raw materials supplied) |

| Applications | Suitable for industrial motors, automotive motors, home appliance motors, power tools, automation equipment, etc. |

| Customizable Items | Custom molds, material thickness, punching locations, and dimensions can be customized based on customer drawings and specifications. |

Jiaxin's high-precision hot-dip galvanized metal stamped motor cover are deep-drawn and precision-stamped using a 300-ton high-tonnage press, ensuring crisp contours, precise dimensions, and tight tolerances. Made from premium DX53D+Z hot-dip galvanized steel, specifically designed for deep-drawing and complex forming, its excellent ductility ensures integrity during processing, while the hot-dip galvanized coating provides strong corrosion resistance, effectively resisting harsh operating environments such as moisture and oil, significantly extending the motor's service life.

The source factory that provides high-precision OEM Metal Stamping Parts solutions

Source factory, powerful customization, each motor housing is tailor-made for you

|

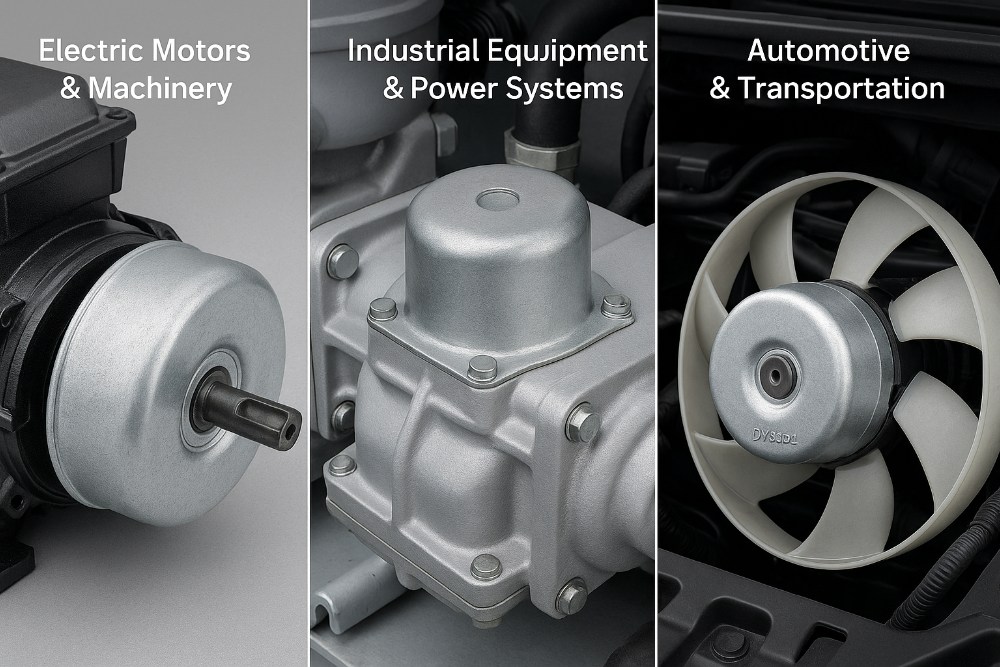

Electric Motors & Machinery |

Industrial Equipment & Power Systems |

Automotive & Transportation |

|

This motor cover is made from DX53D+Z hot-dip galvanized steel and shaped by a 300T stamping process, giving it both strength and precision. Weighing only 196.5g, it adds reliable protection without extra bulk. It helps shield the rotor and stator, keeps the motor running smoothly, and holds up well even in damp or tough working environments thanks to its excellent corrosion resistance. |

Designed as a hardware stretching part, this cover is lightweight yet durable—just 196.5g per piece. The high-strength galvanized material ensures stability when used in power systems, compressors, or automation equipment. Its precise stamping and stretching process help equipment last longer, cut down on maintenance, and deliver safe performance even under heavy loads. |

In automotive motors, cooling fans, and other vehicle electrical systems, this cover’s galvanized DX53D+Z steel and anti-rust surface make it a dependable choice. The high-precision 300T stamping guarantees consistent shape and fit, while its durability means it can handle vibration, temperature shifts, and long-term use without losing reliability. |

Your Vision, Our Customization Mission

Precision Tailoring Without Limits – Your Partner for Bespoke Automotive Solutions

Feedback Provision

Final Approval

Your Supply Chain, Our Integrated Mission

Materials to Assembly – Your Seamless Manufacturing Partner from Raw Materials to Finished Products

As a direct manufacturer with established partnerships with leading material suppliers, we maintain full control over our production processes. This allows us to offer competitive pricing without compromising on quality, ensuring you receive high-performance components tailored to your exact requirements.

Proven Expertise and Reliable Capacity

Backed by extensive experience in serving diverse industries, we combine technical excellence with scalable production capabilities. Whether you require prototypes or high-volume orders, our team is equipped to deliver precision-engineered solutions with unwavering reliability.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Friendly Links :

More ProductsScan to WhatsApp