Electric terminal formed by stamping after nickel plating of red copper material

Item No.:

CWJX-S16004-1Product origin:

Xiamen,ChinaShipping port:

Xiamen,ChinaLead Time:

within thirty daysProduct Name:Red copper electrical terminalRed Copper Nickel Plated Material Metal Stamping Electrical Terminal

Product Description:It is a single terminal made of red copper after nickel plating and stamped by 35t punch

Product specifications

Material quality:Red copper

Single weight:zero point zero eight seven one gram

Product characteristics:High precision

Working procedure:1. Continuous die stamping -- 2. Inspection and packaging

Application:electrical system

Product Detail Display

Stamping video

Customized Products service

Free Customized Design Sample

Any Custom Logo, size, shape is acceptable.

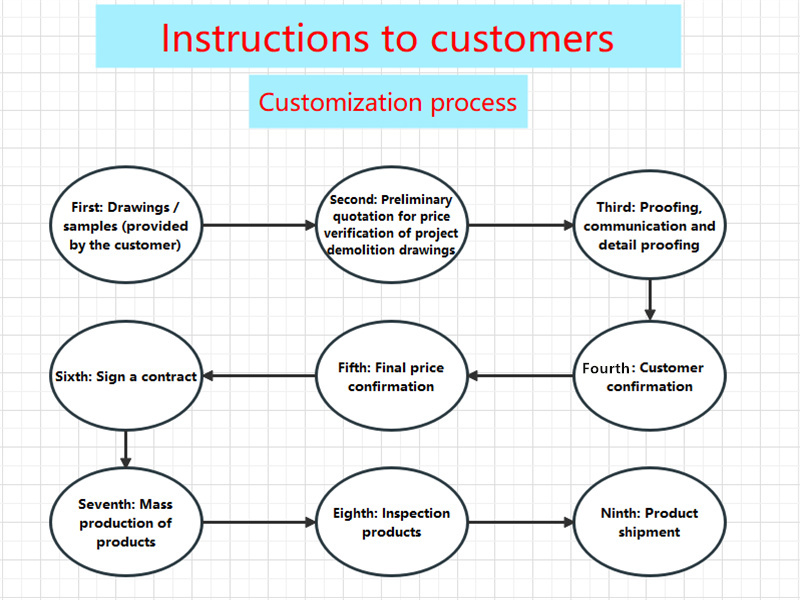

1. Customers provide samples or required product drawings

You can provide us with drawings and samples of a certain product according to your own needs

2. Technical disassembly drawing analysis and testing whether it can be produced

Our engineering department disassembles the drawing analysis to confirm whether it can be produced

3. Determine if it can be produced

If it can be produced, the project will analyze the required material and material specifications according to the drawings provided by the customer, the required mold tonnage, and the production capacity that can be achieved to the business.

4. Business Quotation

The price of comprehensive business materials (PMC will confirm the price with the supplier), the price of surface treatment (the PMC department will confirm the price with the supplier) and other accounting costs before quoting to the customer

5. There is no objection to the price, make a sample to the customer for confirmation

If the customer agrees with our quotation, the mould will be made, a small number of samples will be produced, and the samples will be sent to the customer for confirmation

6. The samples are confirmed to be correct, and the contract is signed for mass production

After the sample is confirmed by the customer, the contract is signed for mass production.

7. Arrange for factory production--packaging--warehousing--shipment

Previous :

Metal Stamped Stainless Steel Terminals For Oven Lamp Cap Plug ContactNext :

Cold Rolled Steel Sheet Precision Metal Stamping Terminal Plug Iron Sheet FastenerIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported

Friendly Links :

More ProductsScan to WhatsApp